Flow through pipe

Flow

Through Pipe

Introduction of fluid

Fluids are any substances

that can flow. Fluids are defined as either liquids, gases, or mixtures of the

two. They are tangible, take up space, and have a finite mass. They are

materials that are composed of various molecules or particles. When the substance's

particle's relative position with respect to time changes, they are said to be

flowing. The fluids' new qualities include:

· There

are no shapes in it.

· It

takes up the shape of the pipe or vessel through which it is flowing.

· It

can swell beneath its weight.

· It

does have a mass of its own.

The study of force and its effects is known as

mechanics. Surface force and body force are the forces that are exerted on the

fluid (Gravitational force)

Fluid flow inside pipeline

A sort of flow that

occurs inside a closed conduit at a specific pressure is called flow-through

pipes or fluid flow. Open channel flow is another type of flow. In various

piping and pipeline systems, these fluid flows are used to convey chemicals,

petroleum products, gas products, sewage flows, home water supply, etc.

Since all real fluids

have some degree of viscosity, the flow of all real fluids is known as viscous

flow. The physical characteristics of the pipe and the external forces

affecting the piping system by displacement and loads are similar to the shear

stresses or frictional forces between the fluid layers and fluid to a solid

surface. The pipe system is impacted in numerous ways by the fluid's flow and

flow characteristics.

Theory behind the pipe flow

Fig 1: Flow through pipe

Imagine a pipe with

laminar fluid flow. The water molecules will slow down and come to a complete

stop close to the pipe walls as a result of surface contact between the water

and the wall. Due to friction, this layer of water molecules will also force the

adjacent layer to flow of water to slow down. Water drops in the pipe's core

must maintain a constant velocity to make up for this velocity and maintain a

consistent volumetric flow rate. As a result, the velocity boundary layer

begins to form along the pipe's boundary walls and progresses in the flow

direction until it reaches the pipe's centre. The hydrodynamic entrance length

is the distance from the pipe inlet to the location where the boundary layer

combines. The completely developed region is the area that extends past the

hydrodynamic entrance length.

How

does Fluid flow in Pipes?

There is always some

energy causing the fluid to flow, no matter where it is. The flowing fluid has

three main types of energy: flow energy (pressure head), kinetic energy, and

potential energy. There are essentially two reasons why fluids go via pipes.

1. Tilting the pipes to create a downward flow in the case where gravitational energy is converted to kinetic energy.

2.

The second method involves applying more pressure to one end of the pipe than

the other end in order to generate a pressure difference between the two ends

using different kinds of pumps. Fluids are accelerated into the discharge line

by means of impellers, which are connected to the motor. This affects the

system's internal flow rate. The piping system that the pump is linked to does

not control the pressure or flow rate that the pump will deliver.

Losses in Flow through Pipes

Energy will be lost each

time a fluid flows inside a pipe. The losses that occur while fluid moves

through pipes can be divided into:

1) Major losses

2) Minor losses

Major Losses: This is due to the pipe wall friction.

They are frictional

resistance forces that depend on the fluid density, surface type, fluid

properties, and solid wall in contact while being pressure-independent and

proportionate to volume. The following formulas, the Darcy Weisbach equation

and the Chezys formula, can be used to compute major losses:

Fig. 2:

Darcy Weisbach Equation

Minor losses:

Eddy formations in the fluid, brought on by abrupt increases in (contraction)

and decreases in (enlargement) of fluid velocity, result in energy losses. due

to barriers, pipe bends, and pipe fittings.

Types of fluids

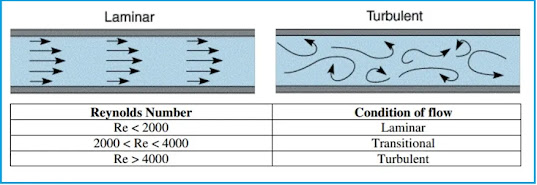

Laminar or turbulent flow

are two different forms of flow that can pass through a pipe. The Reynolds

number (Re), a non-dimensional number, is used to categorise different types of

flow-through pipes.

Re =ρVD /µ

Where, ρ is the density of the

fluid, V is the average velocity of flow, D is the hydraulic diameter and µ is

the coefficient of dynamic viscosity.

Laminar flow

Laminar flow is the

gradual, layer-by-layer motion of a fluid in a pipe with little or no mixing.

Usually happens when the fluid is extremely viscous and the velocity is low.

The centre of the pipes will have the highest flow, while the pipe walls will

experience the lowest flow. (Refer fig no 3)

Fig.

3: Laminar vs Turbulent Flow

Turbulent flow

When the flow velocity in a pipe surpasses a certain threshold value, or when the velocity is high. With time, the fluid's flow turns turbulent and fluctuates in an erratic manner. The average flow velocity and the velocity at the pipe's centre are roughly equal.

Fig 4: Reynolds schematics sketches of pipe flow transition. (a) Laminar

viscous flow at extremely small velocity (b) Transitional flow as the velocity

increase and (c) Turbulent flow at high velocity

Impact of Fluid Properties on Flow through Pipes

The piping system through which the fluid is flowing is significantly impacted by the fluid's characteristics.

When the fluid density is higher, the

mass will also be higher, making the system compact and dense. This is known as

density (mass/unit volume).

We must modify the performance of

the pumps to compensate for the increased shear resistance as the fluid

viscosity rises. Typically, there will be a slight decrease in intake, a larger

decrease in head or pressure, and an abrupt spike in power draw.

The fluid's pressure and velocity are

inversely proportional to keep the algebraic total of the potential, kinetic

energy, and pressure constant, hence Bernoulli's principle states that as

pressure rises, velocity falls.

The fluid qualities like

density, velocity, and viscosity that affect the fluid flow in the piping

system are influenced by some system factors.

• The fluid's viscosity

and density will vary as a result of the temperature change.

• The inner diameter and

length. The internal roughness of the pipes in a turbulent flow.

• How supply and

discharge containers are positioned in relation to the pump.

• Adding rises and falls

to the existing pipe layout.

• The quantity and

variety of bends in the system.

• The system's total

number of valves and other pipe fittings.

• The pipework's

conditions at the entrance and exit.

The specific gravity

(relative density) [density of fluid/density of standard fluid] is another

crucial characteristic of the fluid.

The outlet pressure varies according to the change in density when the

fluid's specific gravity is changed. (Lighter fluids exert less pressure.)

Surface tension will have a growing hold-up, causing the pressure drop to

become unaffected.

Conclusion

A thorough analysis of flow through pipes has been conducted, and

different frictional losses have been researched. That includes the description

of flow through pipes in this page, as well as the effects of fluid

characteristics on flow through pipes.

Guided By:- Prof.Dr.Nitin Borse.

By:-Om Panchal, Parth Gupta, Rohit patil, Vishal Patil, Mayuri pawar.

.gif)

Great👍👍

ReplyDeleteNice information and neat and well label diagram

ReplyDeleteVery well explained

ReplyDeletevery informative information

ReplyDelete